Cognac different production stages

Cognac is made from “grapes“, and more specifically 98% from Ugni Blanc. Other grape varieties are used in the Cognac region, such as Folle Blanche, Colombard and Follignan, they account for the remaining 2%. Before being pourred in our glass, Cognac undergoes a long production process. In this blog post, we’ll summarize its various stages.

The wine nursery

There is a primary stage in the planting of young vines in the vineyards: the vine nursery. The job of the vine nurseryman is to produce vines adapted to Cognac distillation wines, from the above-mentioned grape varieties.

Let’s look at its different phases :

- Preparation of wood and grafting stocks: this consists of selecting wood several metres long from the mother vine, in order to cut it below the bud into several small woods called “grafts”.

- Graft selection: the grafts are cut and then grafted onto the upper part of the rootstock after the bud has emerged from the scales.

- Grafting: as the name suggests, grafting consists of grafting the rootstock and the scion together to produce a plant. Once grafted, the plants are consolidated with kerosene to heal the graft (commonly known as stratification).

- Planting and cultivation of the nursery: first, the plants are planted in a warm, bright environment with some humidity to encourage their development and limit losses, diseases and anomalies until the roots develop.

- Plant sorting and storage: after the plants have been pulled up after leaf fall, they will be sorted. Those with at least 3 roots, each 10 cm long, will be waxed again, but only the roots will not. They will then be stored in a cold room until they are planted in the vineyard.

The vine cycle

The vine cycle continues every year. It begins with the grafts we’ve just bought from the nurseryman. First of all, the vineyard manager begins to prepare the soil before planting, which generally follows in the spring. To ensure optimal growing conditions, the plots are meticulously cared for to encourage the establishment and development of the plants.

Three years later, after several prunings, the well-grown vines are ready to produce grapes in good quantities, and above all, the first bunches of grapes suitable for vinification. This is the first production cycle.

To ensure optimum vine health, work on the vines generally begins in February, with pruning to regulate vigour, growth and future harvest load per vine. Then, towards the end of May and the beginning of June, we carry out pruning, which helps to raise the vine’s foliage so that the sun can penetrate better and bring to maturity a large number of bunches per vine. Last but not least, the harvest! In mid- to late-September (i.e: 2023), the bunches of grapes are picked using a harvesting machine (and more rarely by hand), trying to avoid foreign plant material (leaves, etc.) as much as possible.

Winemaking process

Following the harvest, in the same period, comes the process of vinifying the crop. Pressing is the first step in transforming grapes into must, which is then rapidly transferred to a vat to add the yeast needed for fermentation. The fermentation process lasts 4 to 8 days, producing wines with a high acidity and a volume of between 9 and 11° vol. Daily oenological monitoring (1) of fermentation by measuring density (editor’s note: transformation of must sugar by yeast into alcohol) and must temperature enables us to track progress and correct any anomalies. Finally, the wines are kept in vats until the distillation process, without the addition of sulfites.

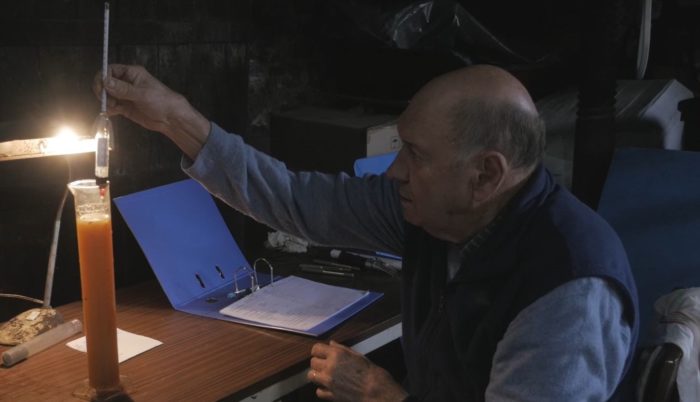

Double distillation :

The Charentaise double distillation process transforms wine into Cognac by heating it twice. Wine distillation separates the aromatic and alcoholic compounds from the vinasse (water and less volatile substances).

The first heat: consists of retaining only the volatile substances that come from the wine, to obtain a brouillis, or distillate, from the wine, with an alcohol content of between 27 and 32°.

The second heat: also known as the 2nd pass or “bonne chauffe“, it distills the brouillis into Cognac eau-de-vie at around 72°, its the “quintessence”. This eau-de-vie is colorless and limpid, only the heart of it is selected for the next steps.

An important step in the distillation process is tasting and smelling the eau-de-vie. They enable us to find the right moment to obtain this famous “heart” of the eau-de-vie, and thus a perfect distillation product, ready for ageing.

Ageing

The ageing of eau-de-vie, otherwise known as “élevage”, begins when the eau-de-vie is placed in a wooden cask (the Limousin oak cask being the most commonly used) in a cellar, to allow the Cognac eau-de-vie to reach the maturation stage required by the Cellar Master to create his blends.

During its maturation process, there are plenty of possibilities to give the Cognac a different aromatic profile, only one Cellar Master can decide which is the most convenient container depending on the result he is seeking.

- New casks : casks that have never been used to age an eau-de-vie. Often used at the start of the ageing process, so that the wood’s tannins can mellow with age, giving Jean Fillioux Cognac aromas of vanilla and sweet spices.

- The “red” barrel (ndlr: second-fill or “fût roux” : this is a barrel that has already contained cognac. It is in this barrel that the eaux-de-vie will remain the longest during their ageing process.

- Old casks : old casks are those in which the wood’s tannins are no longer present. Often used to store mature eaux-de-vie before bottling or dame-jeanne (2).

- The dame-jeanne : no longer made of wood, the dame-jeanne is used to store eaux-de-vie that have reached a perfect aromatic balance and will be used for blending very old eaux-de-vie. They are often stored in paradise.

During the ageing process, the age of the eaux-de-vie is counted in “compte de vieillissement”, otherwise known commercially as VS, VSOP, XO and XXO. The ageing count starts from distillation with count 00 up to count 14. If you’d like to find out more, please visit our blog article on the subject of Cognac ageing.

Blending skills

The final part of the creation process, blending, is the art of the Cellar Master, who uses his creativity and experience to create an eau-de-vie that is built from the start to the finish, and which for us is the culmination of a long process of elaboration (with the exception of Single Cask, that by essence is only one eau-de-vie).

The cellar master selects the eaux-de-vie he wishes to blend, in order to marry them together and find the best harmony for an excellent result. He may use only single-cru eaux-de-vie (like our Grande Champagne). But he can also vary the Crus by using a certain % of Grande Champagne, Petite Champagne, Borderies, Fins bois, Bons bois and Bois ordinaires to give a multi-cru Cognac. Or a Fine Champagne Cognac, which is a blend of eaux-de-vie made exclusively from Petite and Grande Champagne, with a minimum of 50% Grande Champagne (we’ll defintely write one for the blog on the topic later).

Glossary :

- (1) Science of wine.

- (2) A large, generally thick glass carboy with a very rounded shape and a short neck.